Home / Services

Products and services

Surface treatment of metalware - main material include Iron, Copper, Aluminum, Zinc, stainless steel.

Selection of substrate material

1215

Sulfur-containing free-cutting steel

1015

JIS S15C low carbon steel

1018

Low carbon steel

4140

Alloy JISG4105 SCM435 ~ 440

Plating color

Trivalent Chromium Zinc plating

Product Performance

Trivalent Chromium Zinc Plating is the most basic surface treatment process. The plated Zinc layer on metals, alloys, or other materials can most express diversity of products, and change colors of surface according to customer request.

In addition, it provides added value of products by giving metallic luster to provide cosmetic upgrades and rustproofing of product, preventing substrate from abrasion, elevating conductivity, lubricity, tensile strength, thermal resistance, weather resistance as well as preventing carburizing or nitriding during heat treatment.

Advantages:

Highly uniform coating thickness

Glossy surface excellent

Corrosion resistance excellent

High ductility

Salt spray test up to 48~120 hours

(according to customer requirements)

Coating thickness from 8um to 20um

(according to customer requirements)

Trivalent Chromium yellow Zinc plating

Product Performance

It uses trivalent Chromium eco-friendly production process excluding hexavalent Chromium. With HYPRO trivalent Chromium passivation agent, the process gives uniform gold/yellow color and provides excellent corrosion resistance. Color of appearance is adjustable

Hexavalent Chromium yellow Zinc plating

Product Performance

The conversion coating agent for conventional hexavalent chromium yellow Zinc plating is used. Combined with chromate and Zinc plating passivation, the process produces clear reddish green coated appearance on the plated surface.

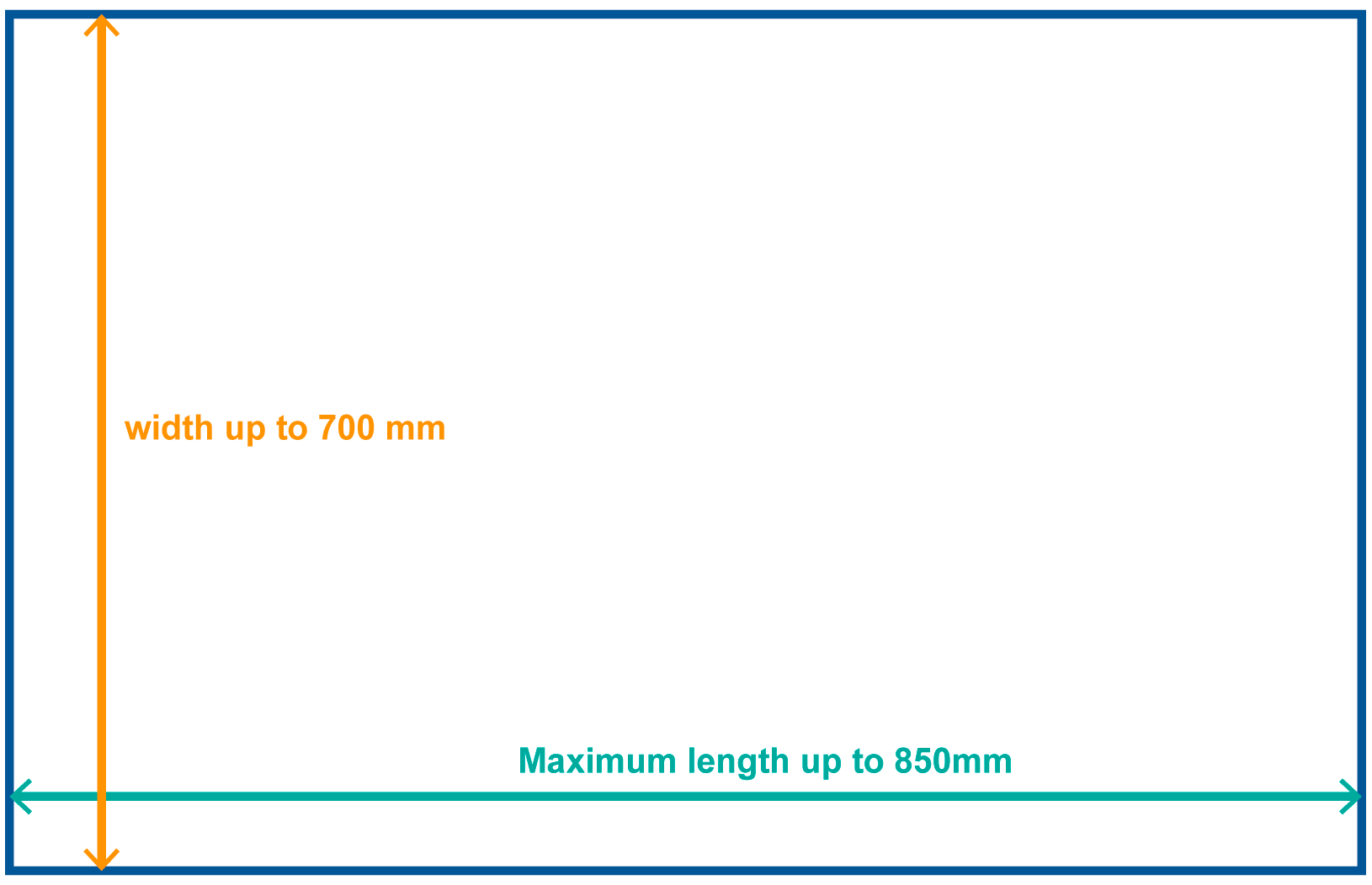

Dimensions of plating

Maximum length up to 850mm and width up to 700 mm.

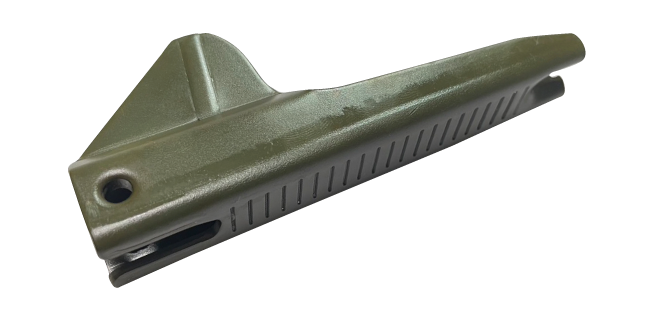

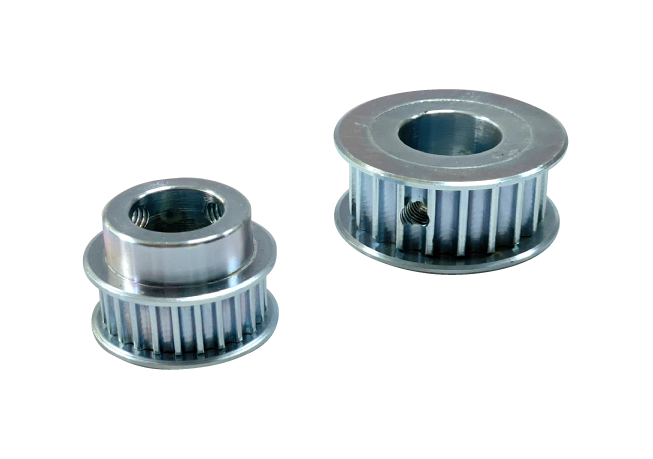

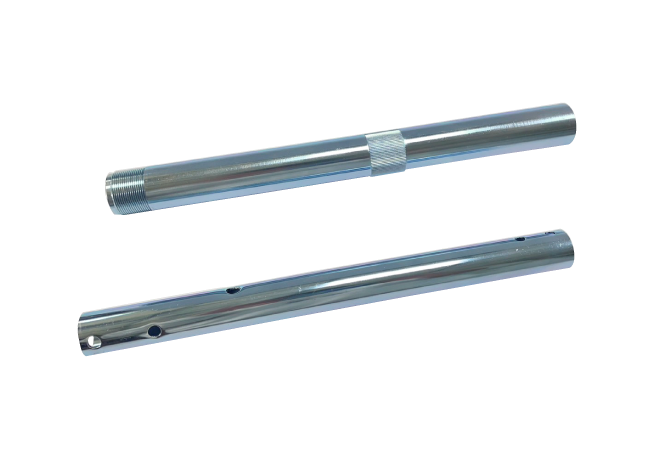

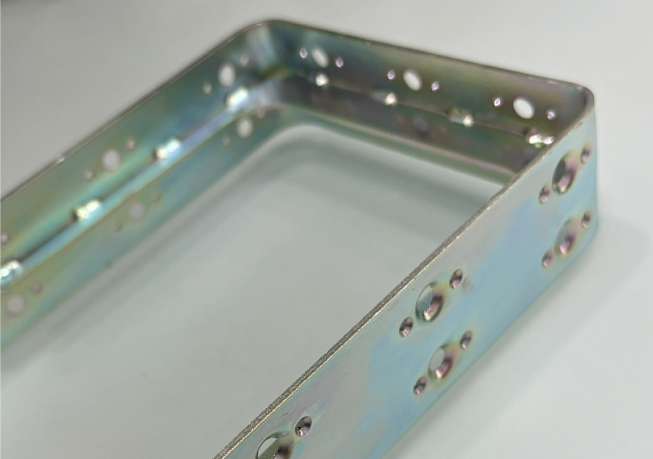

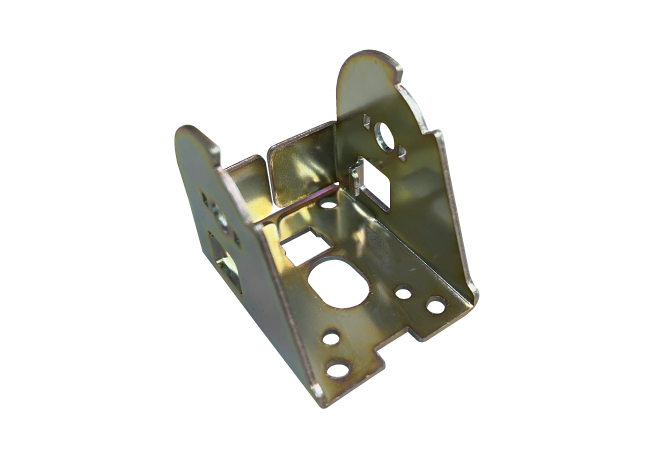

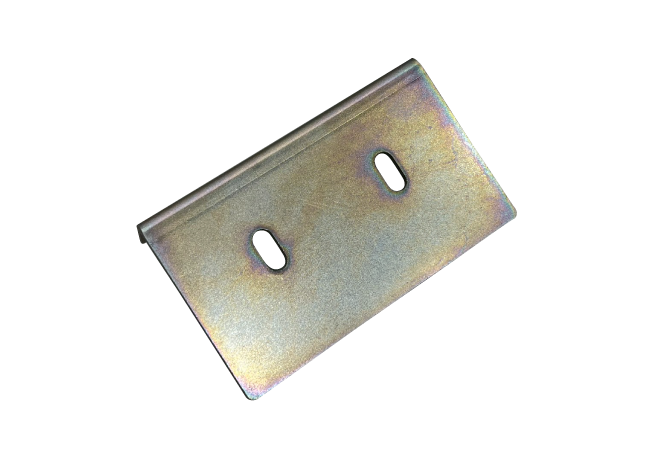

Product showroom

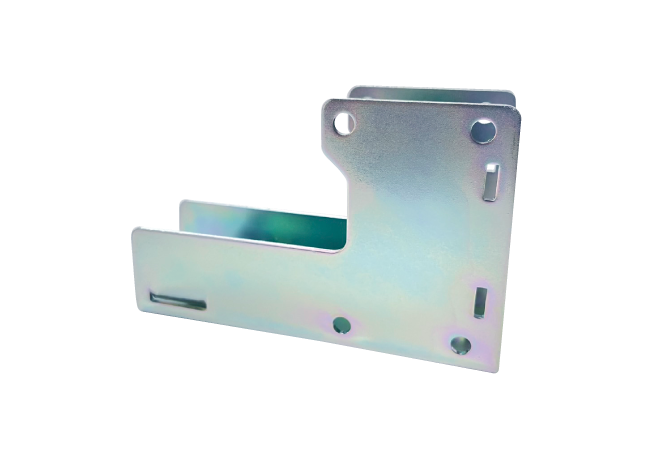

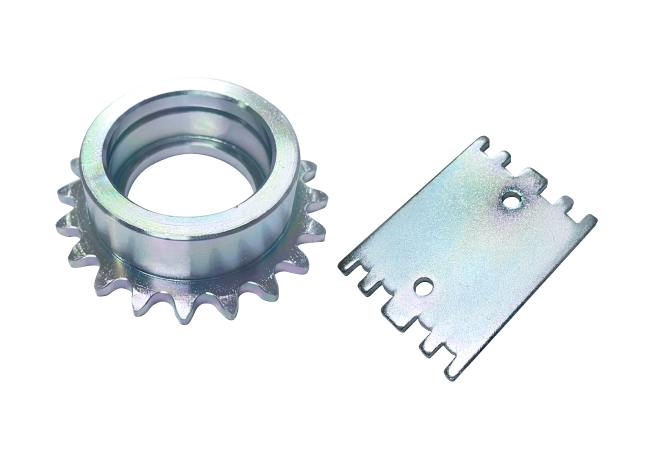

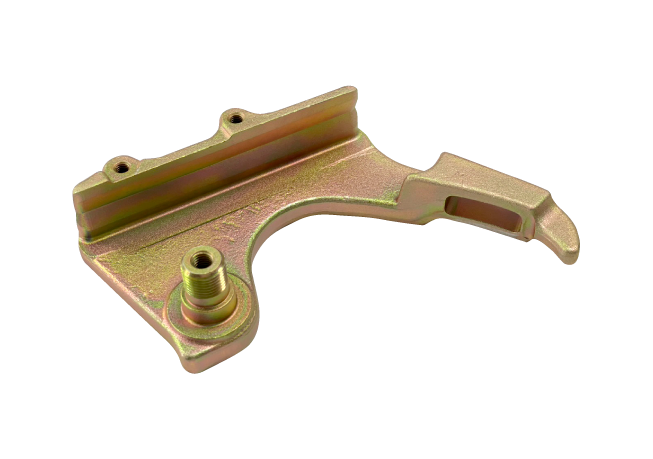

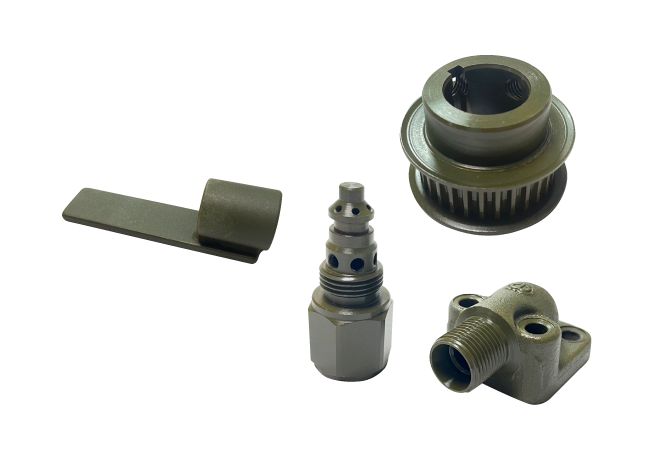

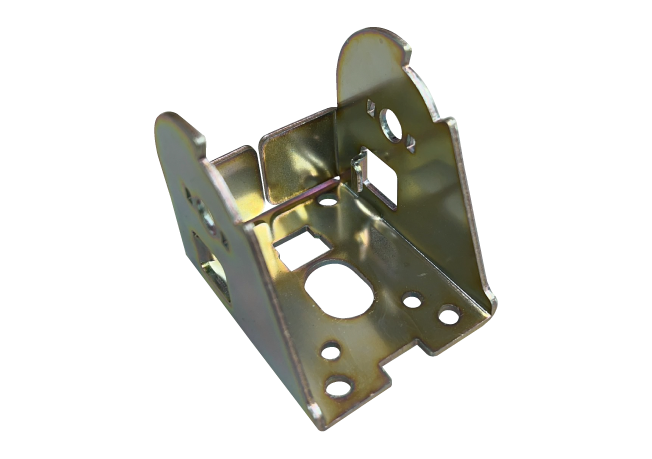

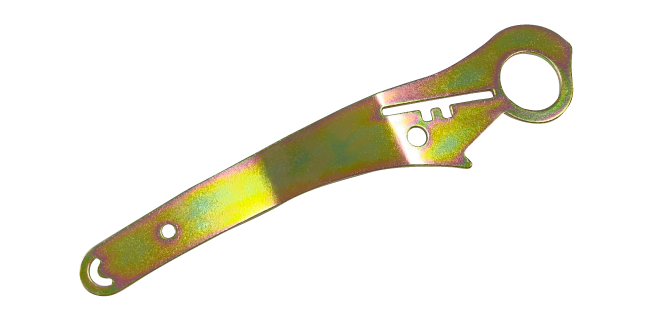

Trivalent Chromium Zinc plating

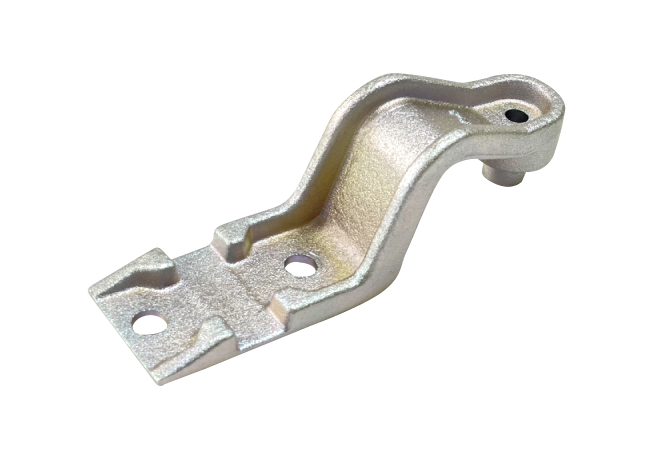

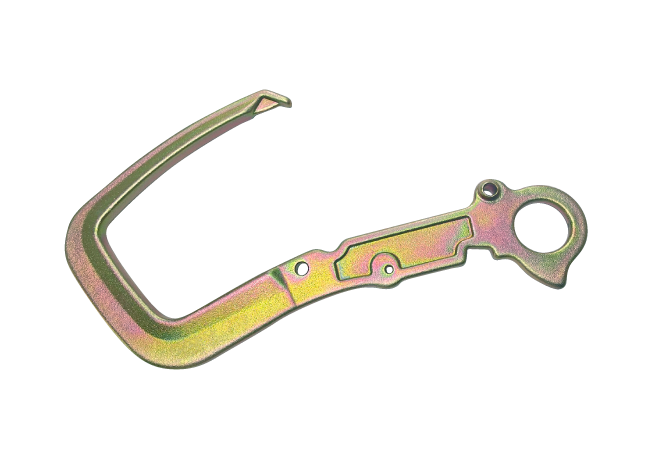

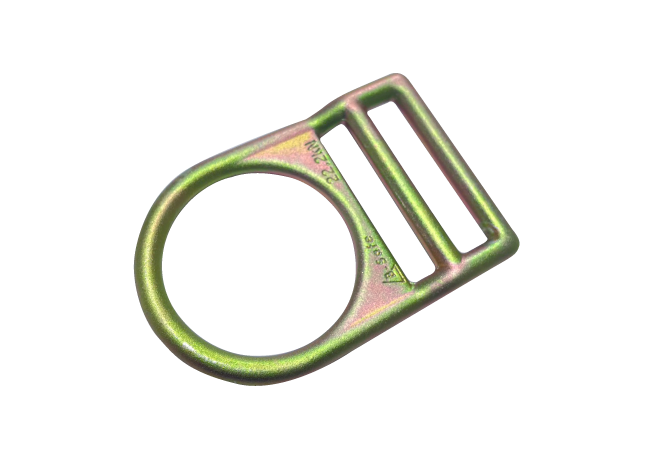

Trivalent Chromium yellow Zinc plating

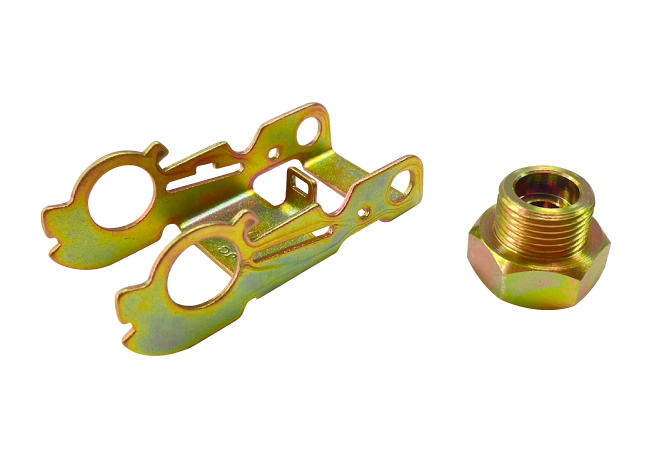

Hexavalent Chromium yellow Zinc plating

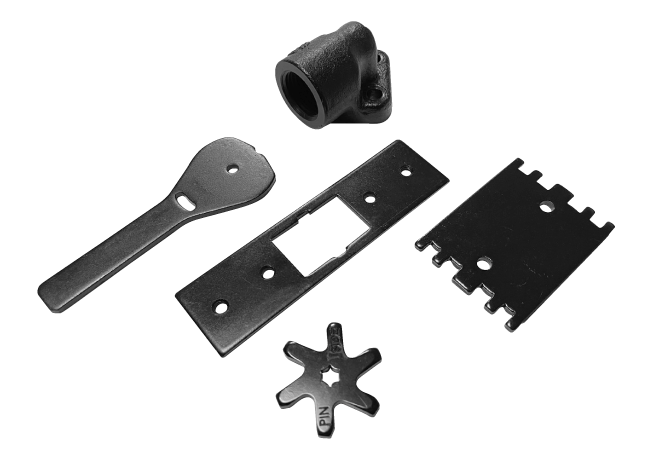

Hexavalent black chromate Zinc plating

Army green